Fashion Apparel Design: The Ultimate 2026 Guide for Brand Founders

Want to launch a fashion brand but don’t know where to start? This guide was created by Amanda Rango of ARD Fashion Consulting. A designer with over 25 years of experience, to provide essential information and an Ultimate Guide of what to expect and how to get started.

From global sourcing shifts to the rise of 3D tools and AI-driven design, the path from concept to collection is full of moving parts. The good news? You don’t need to be an expert in all of it, you just need to start with the right framework and support.

At ARD Fashion Consulting, we work with early-stage founders to map out realistic launch plans, so they don’t waste time, money, or momentum figuring it out alone.

In this guide, we’ll walk you through:

What steps matter most in today’s landscape

When to start them

Why they can make or break your launch

Let’s build your 2026 production plan with clarity, not chaos.

What is Fashion Apparel Design in 2026?

At its core, fashion design remains about product and purpose, but the tools, timelines, and expectations have evolved.

A few major changes shaping 2026:

3D prototyping and digital sampling are speeding up development and reducing waste

AI tools are helping with forecasting, ideation, and supplier research

Tariff changes and global politics are pushing brands to diversify sourcing beyond China

And customers are smarter and more values-driven, especially around sustainability, size inclusivity, and price transparency

The bar is higher, but so is the potential. A thoughtful, well-prepped launch in 2026 can set you up for long-term success, not just a short-term drop.

Step 1: Research, Trend Forecasting & Market Clarity

What this is:

Before you design anything, you need a clear perspective:

Who are you building for? Why now? And what gap does your brand fill?

Trend research isn’t just about what's cool this season: it’s about understanding your target customer’s lifestyle, habits, and values, and how your product fits into their world.

We help founders zoom out to identify cultural shifts, market white space, and style inspiration — then narrow in with tools like Pinterest, WGSN, and real-world observation to shape a collection that feels timely and personal.

When to do it:

Start at least 9–12 months before launch (even longer if you’re building a full brand).

This phase sets the tone for everything that follows.

Why it matters:

Too many collections fail because they lack clarity. When you define your brand’s point of view and ideal customer early, you make every design, sourcing, and marketing decision easier, and more effective.

Step 2: Design and Development

What this is:

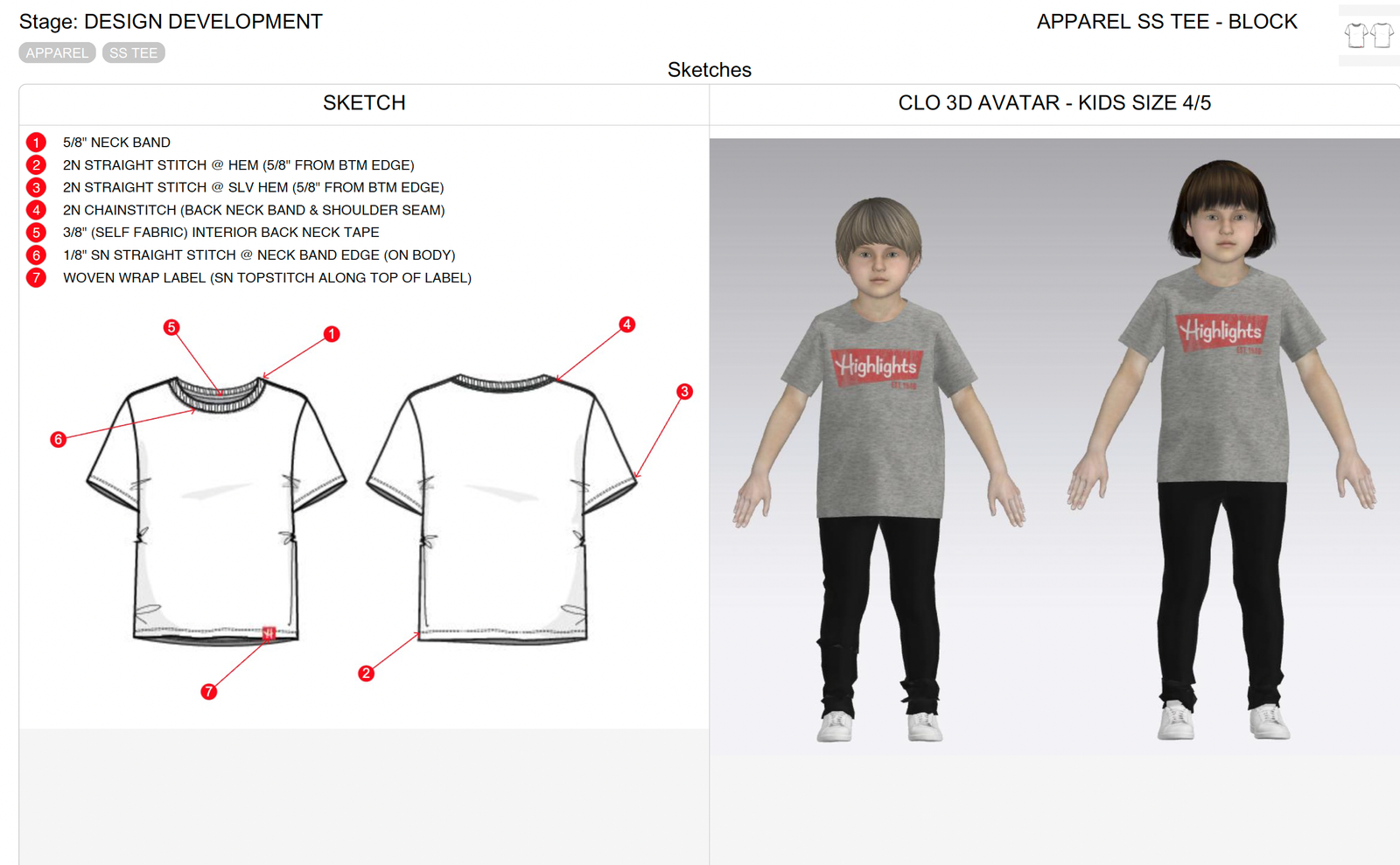

This is where your ideas become a collection. You move from loose concepts to technical design, with sketches, specs, and fabric direction to communicate your vision clearly to your vendors and partners.

Design isn’t just about creativity; it’s how you translate vision into execution. You’ll choose silhouettes, define materials, and begin creating the tools your factory needs to bring it all to life.

We recommend using:

Techpacker.com – for building tech packs & managing product data

Adobe Illustrator – for clean, scalable sketches

Pantone.com – for color accuracy and consistency

When to do it:

Start this phase 7–9 months before launch, once your concept and customer strategy are clear.

Why it matters:

Factories don’t guess, they build what you show them. The more detailed and accurate your designs, the fewer revisions you’ll need later. This step is essential to control costs, minimize back-and-forth, and build quality from the start.

Bonus Insight: Digital design tools (like 3D rendering) are becoming more accessible, helping speed up timelines and reduce waste. If you’re working on a tight budget or timeline, digital development can be a powerful tool.

Sketch vs. 3D Avatar

Step 3: Sourcing and Supplier Strategy

What this is:

This is where you choose the materials, trims, and manufacturing partners who will bring your collection to life, and ensure it’s made with quality, ethics, and profitability in mind.

We help our clients source from trusted, global partners, primarily in China, India, Bangladesh, Turkey, and Peru, and we’re constantly vetting new factories to keep sourcing flexible and diversified.

Why that matters:

Tariff shifts and geopolitical tensions are affecting lead times and costs

Sustainable materials (especially natural and organic fibers) are rising in demand

Founders need to stay nimble to pivot fast without sacrificing quality

When to do it:

Begin sourcing 6–8 months before launch, right after your tech packs and materials list are ready.

Why it matters:

The right vendor can make or break your product. A smart sourcing plan keeps you in control, from lead times and minimums to pricing and production ethics.

Pro Tip: Always ask about minimum order quantities (MOQs), lead times for materials, and whether the factory offers small-batch production for newer brands

Step 4: Sampling, Fit & Building for Real Bodies

What this is:

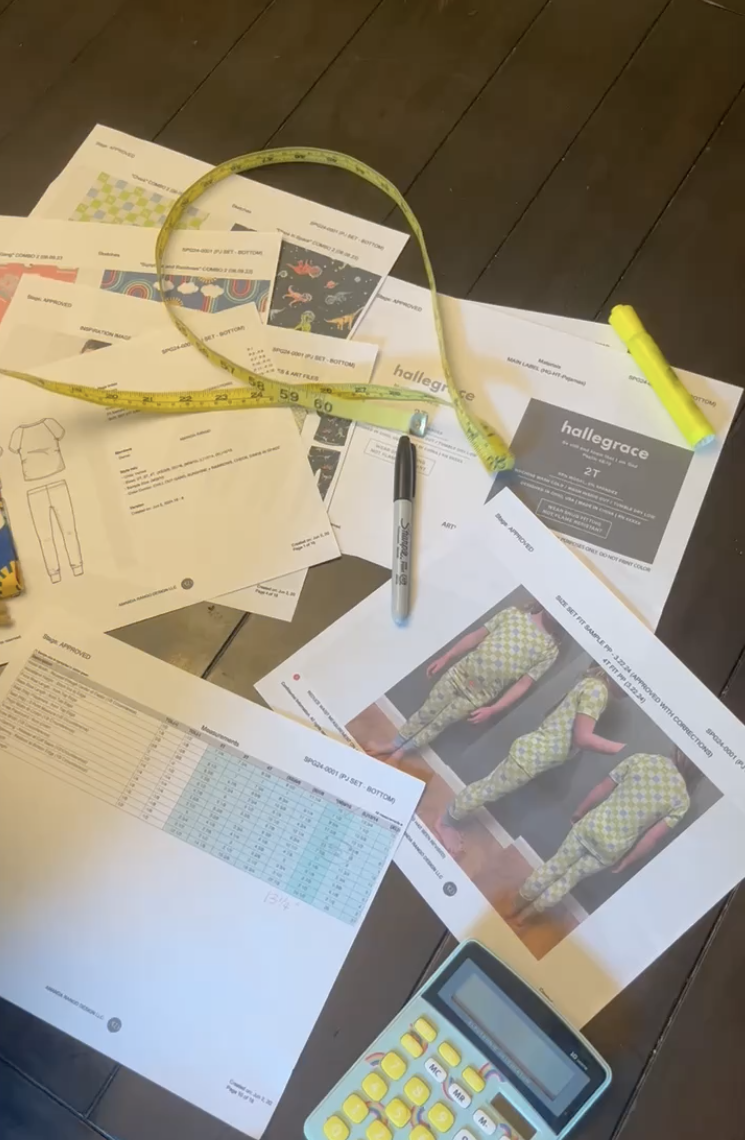

Once your designs are vendor-ready, your factory creates physical samples, starting with protos and fit samples that help you evaluate construction, comfort, and sizing across real bodies.

This is also where you define your fit standard, not just by size, but by proportion, comfort, and movement.

At ARD, we encourage founders to consider:

Realistic fit models (who reflect your actual customer, not just industry “fit size”)

Fit forms for consistency and a standardized baseBody diversity—because not all mediums are created equal

When to do it:

Start sampling 5–7 months before launch, and allow time for at least 2–3 rounds of revisions.

Why it matters:

Fit is one of the top reasons customers return or repurchase. The more thoughtful you are during sampling, the more trust and loyalty you build.

Founder Tip: Sampling takes longer than most expect. Build in time for shipping, revisions, and feedback. Rushing this stage leads to costly production mistakes down the line.

Step 5: Production, POs & Partnering with Your Factory

What this is:

This is the phase where your approved samples go into bulk production, and where your role shifts from creator to project manager.

Your job now is to ensure consistency, timing, and quality as your factory builds your inventory.

That means:

Confirming all POs (purchase orders) are clear and accurate

Monitoring fabric deliveries, trims, and factory capacity

Approving lab dips, strike-offs, and other pre-production checkpoints

Planning for in-line and final quality checks

When to do it:

Bulk production typically starts 3–5 months before launch, depending on lead times and shipping method.

Why it matters:

Even the best factories need direction. Production goes off-track when founders stop tracking. Quality control isn’t just the final step — it’s your brand reputation.

2026 Insight: Global delays are still common. Specialty fabrics (like denim, activewear, and natural fibers) often require longer lead times, so plan buffers into your calendar.

Step 6: Quality Control & Final Approvals

What this is:

Once production is complete, your inventory needs to get from your factory to your warehouse (or directly to your customer). This stage involves managing freight, customs, and delivery logistics.

In 2026, most founders choose from:

Sea freight: cost-effective, slower (5–8 weeks)

Air freight: fast, expensive (2–3 weeks)

Hybrid options: mix of both for speed + savings

You’ll also need to coordinate:

Customs clearance

Freight forwarders

Last-mile delivery (especially for DTC brands)

When to do it:

Schedule freight 2–3 months before launch, depending on shipping method and delivery location.

Why it matters:

Delays here are often out of your control — unless you plan ahead. If you’re launching in Q3 or Q4, be extra cautious around Lunar New Year or holiday congestion.

Founder Tip: Use your TOP samples (Top of Production) for photoshoots and marketing assets while goods are in transit. It keeps your timeline moving — even when your product is still on the water.

Step 7: Shipping, Freight & Getting Your Product Into the World

Once production is complete, it’s time to move your product, but in 2026, shipping requires strategy.

Sea freight is affordable but slow (5–8 weeks).

Air freight is fast (2–3 weeks) but more costly.

Hybrid shipments let you send a few boxes by air while the rest travels by sea, a smart move for early deliveries, photoshoots, or retail drops.

Pro Tip: If you’re shipping by sea, request TOP samples by air so you can start marketing while your main order is still in transit.

Don’t Forget to Plan For:

Customs clearance + duties

Freight forwarding coordination

Last-mile delivery timing

Warehouse check-in and prep

What’s Different in 2026?

Tariff shifts and trade changes are impacting freight costs and lead times

Lunar New Year continues to cause major slowdowns, buffer accordingly

Carrier delays and rising fuel surcharges are adding pressure to the timeline

AI in supply chains is helping big brands plan smarter, you can stay competitive by planning early and staying flexible

How ARD Helps:

We guide founders through freight planning, coordinate with vetted partners, and build buffer time into your calendar, so you launch on time without the stress.

Founder Insight: Your inventory is only useful when it’s in your hands. Don’t let shipping be the reason your launch gets pushed. Read our latest blog, “How to Plan Your Fashion Production Calendar for 2026”, to be ahead of any setbacks.

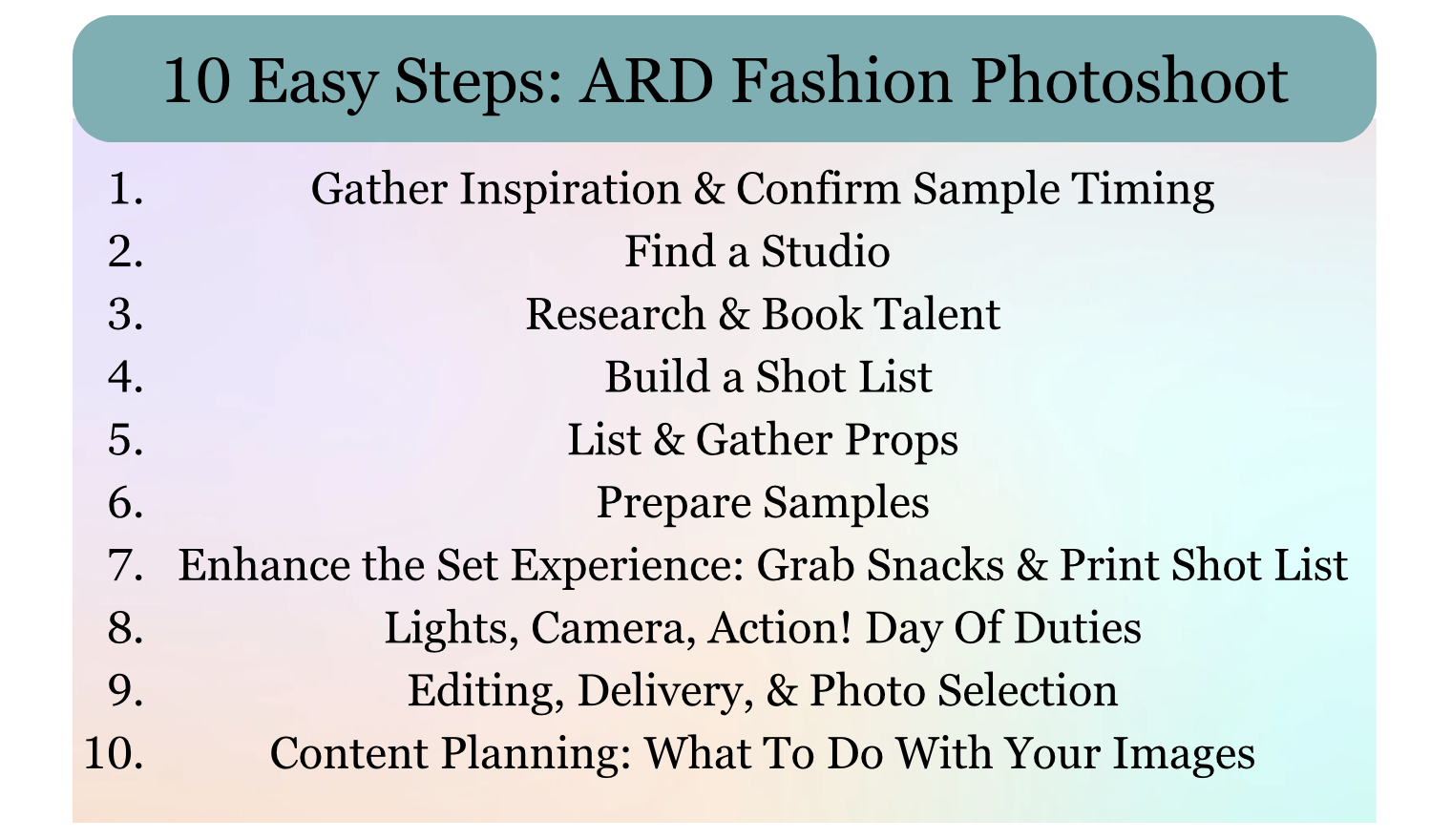

Step 8: Marketing & Launch Alignment

What this is:

While your product is being made and shipped, it’s time to shift focus to your brand presence and launch strategy.

This includes:

Photoshoots (using approved samples or TOPs)

Building your website, line sheets, and marketing assets

Planning out content calendars, email flows, and campaign launches

When to do it:

Start 60–90 days before launch. Your marketing timeline should run in parallel with production, not after.

Why it matters:

Many great products miss their launch window, not because production is late, but because the content, messaging, or platform isn’t ready. Don’t let this be you.

2026 Reminder: Marketing your brand should begin well before launch day. It’s about building interest, community, and conversion over time.

At ARD, we help founders align production and marketing timelines from day one — so launch day isn’t chaos, it’s celebration.

Final Thoughts: Building Your Brand in 2026 Starts Now

Launching a fashion brand isn’t just about a great idea or a beautiful product, it’s about planning, clarity, and execution.

2026 will reward founders who are proactive, resourceful, and customer-driven. From tech packs to tariffs, design vision to delivery, every phase of your brand deserves intention and structure.

And the best part? You don’t have to figure it all out on your own.

At ARD Fashion Consulting, we partner with emerging founders to guide you from concept to launch, without the overwhelm, second-guessing, or costly mistakes.

Ready to build your launch plan for 2026?

Book a Discovery Call to get expert guidance and build your brand with confidence.